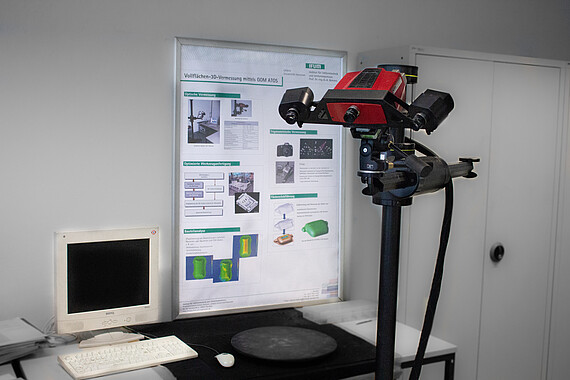

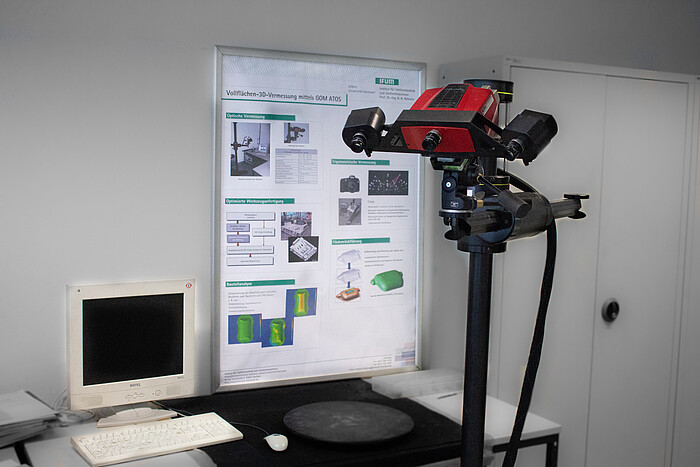

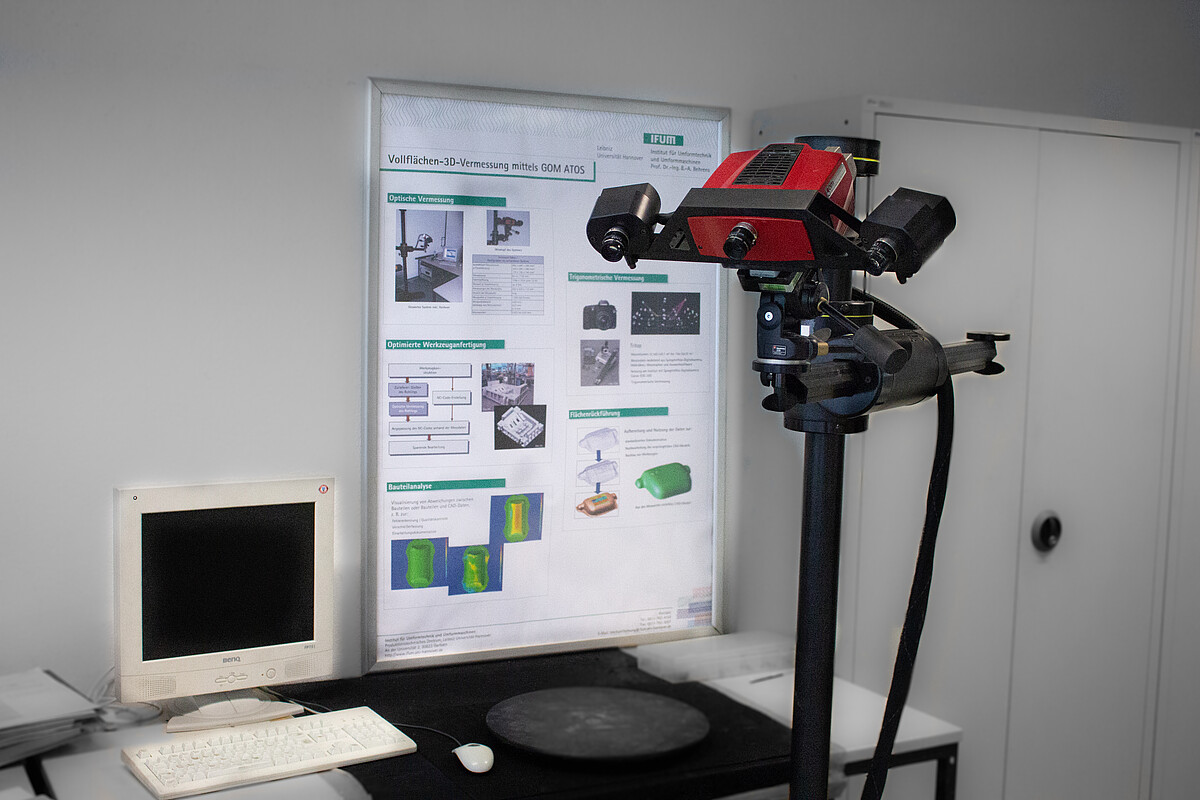

GOM-Atos 2 400

ATOS-Systems are used in many industry branches for the inspection of parts such as sheet metals, tools, moulds, turbine blades, prototypes and injection moulded-parts and pressure die-cast parts. The GOM Atos 2 400 system provides a resolution of a point distance of 0.14 mm. This system can be used to generate 3-D CAD models of a scanned component geometry.

| Parameter | Range |

|---|---|

| Point distance | 0,14 mm |

| Measuring volume | 350 mm x 280 mm x 280 mm (L x B x H) |

| Measurement distance | 750 mm |

| Measurement points per single scan or camera resolution | ca. 1.300.000, 1.280 x 1.024 Punkte |

Dr.-Ing. Sven Hübner

Team Leader

Dr.-Ing. Sven Hübner

Team Leader